It’s wintertime, and the sugar maple trees are awaiting early spring, as are the people who rely on their liquid gold as a source of income.

Vermont produces roughly 48 percent of the maple syrup in the country.

Sugar produced by the leaves during the summer is stored as starch in the roots, and as winter gives way in February, warmer temperatures entice the trees to turn starches back into sugar.

A pattern of freezing and thawing temperatures (below freezing at night and 40-45 degrees during the day) will build up pressure within the trees, causing the sap to flow from the taps.

The sap is mostly water with about 2 percent sugar, and about 40 gallons of sap has to be boiled down to make each gallon of syrup.

Industry growth continues to be positive for maple sugar makers in Vermont.

Last winter, while the ski and snowboard industry may not have fared well, the warm days and cool nights were the perfect combination for the sugaring season, which produced 1,990,000 gallons of syrup — 580,000 gallons more than the previous year, according to the Vermont Maple Sugar Makers Association.

The increased production, though, created an oversupply in the market, which is good news for consumers who can still find last year’s syrup on the shelves and will pay less per gallon this season. But it also means less profit for producers.

Matt Gordon, executive director of Vermont Sugar Makers Association, has been working on ways to boost sales to shrink the gap between supply and demand.

His project was presented to the Lamoille County Maple Sugar Maker’s Association at its annual meeting in Johnson last Friday.

One project in the works is a new design for this year’s syrup jugs. The labels will have a green, gold and cream color scheme, with the green mountains and Camel’s Hump prominently on display.

The term “wild-crafted,” which means the syrup was not produced from cultivated trees, was added to the label in response to consumer surveys completed last year. A VMSMA member seal was also established, and can be added to private-label jugs as well.

The new scratch-resistant wrap-around labels — replacing the silk screen labels — “did pretty well during quality testing in May,” Gordon said. “We saw almost no bubbling in the wrap during rapid cooling. We also shipped a few jugs to see how it would hold up, and didn’t see any tearing or fraying.”

Final proofs of the label will be received this week, and the plastic jugs will go into production soon after, so that they are ready for the March and April haul.

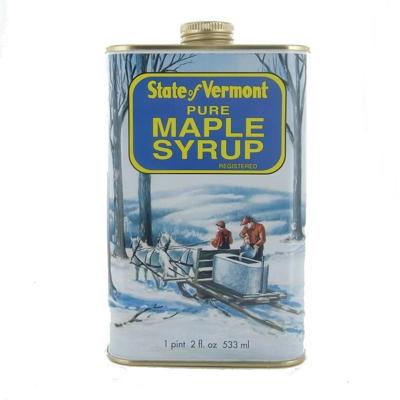

As an association, Vermont maple sugar makers have decided that they will no longer be using the iconic tin cans anymore, because they are “not a great way to store syrup for long periods of time,” Gordon said. They will continue to offer glass bottles.

Quality control

Another project in the works will help sugar makers with quality control.

The flavors of maple syrup vary from producer to producer, from various production systems and different production areas. They can even differ from year to year with a single producer depending on a number of variables from the cleaning solution used in tubing to defoamers used during boiling.

Mark Isselhardt, UVM Extension maple specialist, is creating a reference set to help producers recognize a few of the off flavors.

It is still in production, but the hope is for it to be released this season. The kit has samples of “sour sap,” “buddy,” and “metabolism.”

Sour sap flavors are created when the weather warms near the end of the sugaring season and sap that is left in the tank begins to warm and spoil.

Buddy syrup is also produced late in the season, depending on weather conditions. When the trees begin to bud, the sap takes on an almost chocolaty flavor that is transferred to the syrup. If very strong, the syrup will take on a bitter-chocolate taste.

Metabolism is an off-flavor that is attributed to changes in the metabolism of the tree due to warming temperatures, and can be present at any time during the sugaring season. The resulting flavor has been described by producers as woody, peanut butter, or popcorn. An almost cardboard-like flavor may be present.

While there aren’t samples available for the other 14 or so flavors, there will be a description sheet in the kit.

Isselhardt received a recommendation to add a scratch-n-sniff card to the kit as well, and he said he will consider it.

“Smell is a big part of syrup flavor,” Isselhardt said. “And I always recommend you smell things before you taste them. It’s a good life lesson, really.”

Isselhardt has been working with Across the Fence on video tutorials for maple sugaring as well, and they are available on the Proctor Maple Research Center’s website.

Maple in Every School is also a new concept that is being discussed to boost the industry further. Lamoille County is one of three counties in the state piloting the program.

“A lot of kids in school have never had real maple syrup,” said Arnie Piper, at-large member of the Vermont Sugar Makers Association board. “We want to get it into school kitchens, and the sugar makers in our area who would like to sell syrup to the schools can get on a list.”

Sweet events

This year, the Lamoille County Maple Sugar Makers Association will be hosting Maplerama. Each county in Vermont takes turns hosting the event, and after 12 years, it has come back around to Lamoille.

Maplerama will be August 3-4 at the Hyde Park Veteran of Foreign Wars Post, and will likely consist of a maple contest, a tradeshow, and tours of 18 maple sugarhouses around the county.

“It’s a great way to showcase what our county does,” said Justin Philie, member of the Lamoille Maple Sugar Makers Association. “Many hands make light work, and we are looking for volunteers.”

Philie is also looking for volunteers for Lamoille County Field Days in July as the association runs a building each year selling ice cream, maple cotton candy, popcorn and more. Field Days is where the association makes most of its annual revenue, and a great venue to educate people on the maple industry. Eventually, the goal is to add another building to the Field Days sugarhouse for consumer education and marketing displays.

(0) comments

Welcome to the discussion.

Log In

Keep it clean. Please avoid obscene, vulgar, lewd, racist or sexual language.

PLEASE TURN OFF YOUR CAPS LOCK.

Don't threaten. Threats of harming another person will not be tolerated.

Be truthful. Don't knowingly lie about anyone or anything.

Be nice. No racism, sexism or any sort of -ism that is degrading to another person.

Be proactive. Use the "Report" link on each comment to let us know of abusive posts.

Share with us. We'd love to hear eyewitness accounts, the history behind an article.